rubber impact testing|types of impact testing : wholesalers For tests on elastomers and rubber to DIN 53512 (elastomers and rubber); ISO 4662 (rubber); BS 903 Part A8 Method B (rubber); ASTM D7121 Method B (Schob) . Leading Global Testing Company Uses ZwickRoell Dynstat Impact Testing Equipment to Expand Service Offerings for North American Clients Industry: Academia .

webEpisode #1.16: Com Cenk Torun, Mahassine Merabet, Ali Yagiz Durmus, Hilal Anay. Menu. Filmes. . Programas de TV. O que está na TV e no streaming 250 séries mais .

{plog:ftitle_list}

WEBA 29/08 2023, a Everton jogou com a Cobresal na Primera División.O jogo terminou empatado com um resultado de 2 - 2. Uma vez que o jogo já terminou, sugerimos-te .

This guide outlined the main areas of rubber testing, from natural rubber testing to mechanical testing, with specific details for 30 individual test methods and procedures, .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .

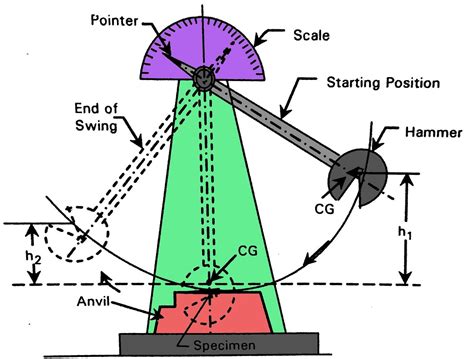

Class J Impact Testing System is widely used for lzod and Charpy impact test on plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced . Are you in the rubber industry and need to understand rubber testing methods? Look no further than this comprehensive guide that covers it all. . involves striking a sample with sudden impact at a steadily decreasing temperature until the sample fractures under impact. Name: Cold Testing. Instrument/Equipment: . How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .

For tests on elastomers and rubber to DIN 53512 (elastomers and rubber); ISO 4662 (rubber); BS 903 Part A8 Method B (rubber); ASTM D7121 Method B (Schob) . Leading Global Testing Company Uses ZwickRoell Dynstat Impact Testing Equipment to Expand Service Offerings for North American Clients Industry: Academia . A low velocity impact study of aircraft tire rubber on 3D textile-reinforced composite plates was performed experimentally and numerically. In contrast to regular unidirectional composite laminates, no delaminations occur in such a 3D textile composite. Yarn decohesions, matrix cracks and yarn ruptures have been identified as the major damage mechanisms under . Standard Test Method for Rubber Property—Resilience by Vertical Rebound D2632-15R19 ASTM . 1.3 A standard test method for impact resilience and penetration of rubber by a rebound pendulum is described in Test Method D1054. 1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for .Rubber Impact Rebound Resilience Tester Elasticity Testing Machine . Description This machine is an energy 0.5J pendulum impact elasticity tester, suitable for measuring the rebound value of vulcanized rubber with a hardness of 30-85IRHD. It meets the requirements of GB/T 1681 "Determination of Resilience of Vulcanized Rubber" and ISO4662 .

what is impact testing

CFH is calculated by impact testing a safety surface with a device known as a Triax impact tester. The Triax uses a head form that, when dropped on the surface, reports measurements of how well the safety surface absorbs the impact. . For example, if you desire a poured-in-place rubber surface for your 8-foot playground equipment, you should . Nader and Ken [5] developed a high frequency testing machine for measuring rubber mount dynamic stiffness up to 5 . The impact test can also encourage the measurement to be done under the real operating conditions i.e. the engine mount which is installed in a real vehicle because the set up is much easier. The rubber stiffness estimated using the receptance functions measured by the impact test and shaker excitation (for both noise and pure tone excitations) are shown in Fig. 8 while the damping coefficients obtained from both methods are shown in Fig. 9. It is evident that the results obtained from both impact and shaker noise excitation agree .

types of impact testing

Commercial, Fitness: Impact-Tile® Features. With over half a million metres sold, Impact-Tiles® have been Australia’s number one gym flooring product ever since its inception. One of the reasons for their wide popularity amongst Australian gym owners, is . The impact technique is a simple and powerful technique because it replaces the cumbersome shaker in the experimental set up for damping measurement. The impact test can also encourage the measurement to be done under the real operating conditions i.e. the engine mount which is installed in a real vehicle because the set up is much easier.

Product name: IS0 180 5.5J Digital Rubber Plastic Charpy IZOD Impact Testing Equipment. Power: 220v 50hz. Impact velocity: 3.5m/s. Center-to-center distance: 335mm. Rubber Testing Machine. Customized Roller PLC Lab Two Roll Mill with Emergency Protection Device.Infinita Lab offers high-quality Rubber Testing services through our vast network of labs in the U.S. From physical and mechanical testing to chemical analysis and environmental performance assessments, our streamlined testing experience ensures your rubber materials meet the highest standards of quality, safety, and regulatory compliance.

Thermal chambers for rubber testing between -70°C and +300°C are also available for the study of material properties at temperatures other than ambient. Our materials testing and force measurement instruments are used by some of the world’s most innovative companies. We specialise in custom materials testing solutions designed to meet the . This study presents the use of rubber grids (RGs) fabricated from end-of-life conveyor belts (i.e. discarded from the mining industry) to improve the performance of ballast tracks. The square apertures of these recycled rubber sheets were cast using a waterjet cutting process. A series of large-scale impact tests were performed on ballast specimens stabilised .Chellappa Chandrasekaran, in Anticorrosive Rubber Lining, 2017. Charpy Impact Test. The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material’s notch toughness and acts .

Class J Impact Testing System is widely used for lzod and Charpy impact test on plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J, and lzod test from 1J to . Although quasi-static test results indicate that the HH and LH rubber elongation to break are approximately 220% and 350%, from a series of simulations, the failure elongation estimated to be 120% and 170% under high strain rate. According to SHPB test, in high strain rates, rubber material behaves stiffer.Service. Measurement of impact toughness of polymers and rubber materials. Standards. ISO 148. Price. Price on tender. Delivery time. The test can be carried out as soon as the samples have arrived to the lab, results are given within a maximum of two weeks, depending on the amount of samples.

Impact testing is a critical step in ensuring the safety of plastic products. This article explains the importance of impact testing and how to perform it. . Charpy and Izod impact tests are most frequently conducted on rubber and plastic specimens using the Class J Automated Impact and Izod Impact Testing system. Tensile impact pendulum and .Impact Test Balls The Impact Test Ball is a specially machined ball to test impact resistance according to IEC, CSA and UL Standards. It is made of chrome-plated-steel for durability, and is fitted . UL 1082 ITB82 Rubber Ball 149.7 grams IEC60529, 61032 ITB125 12.5 mm diameter ball NR IEC 60529 ITB225 12.5 mm diameter ball with handle NRTCR has a comprehensive range of Mechanical Testing services with a dedicated in-house machine shop that assists in sample preparation. Test specimens are duly prepared for metallic and non-metallic materials for the evaluation of Tensile, Compression, Impact, Weldability, Fatigue and Bend properties.

what impacts get blood test

Impact Test. The most common method for measuring the resilience of rubber is by impact rebound testing. This test involves dropping a piece of metal from a predefined height onto a fixed rubber specimen. The height of the metal’s rebound is then measured with a resiliometer. The impact test, however, cannot be used in place of a vibration test.

Carbon Fiber and Silicone Rubber Agai nst Impact test and Shoot Strength Sakuri Sakuri 1 *, Tris Sugiarto 1 , Bambang Sugian toro 1 , Sutarno 1 S.Faqih 1 ,Charpy and Izod Pendulum Impact Testing for Plastic and Rubber Specimens. Special Offers. Watch Video Get Catalogue Get Brochure Request Quote Standards. DIN 53512, ASTM D 1054, ISO 4662. . This prevents movement or slippage that could impact test results' accuracy. HardTest - Intuitive Software: This software interfaces with the Pendulum .

7 de jan. de 2016 · Deriosama40 Hace 8 años 10. En los Final Fantasy no hay orden cronológico, cada uno es diferente de otro, pero algunos tienen secuelas o precuelas. .

rubber impact testing|types of impact testing